JWC-01 | Jumbo Plastic Wheelchock

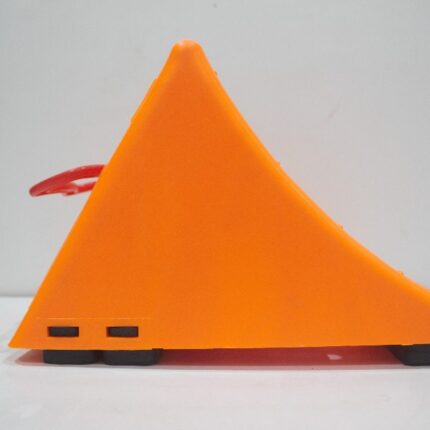

JWC-02 | Jumbo Plastic Wheelchock

Jumbo Wheel chock is manufactured with highly durable, lightweight polyurethane construction. Our JWC-2 is ideal for use with heavy equipment such as haul trucks, loaders, and cranes & Container Lifters like Kalmar Container Lifter Reach Stacker.

Material: UV Stabilized Polyurethane with Traffic Yellow Colour. Tough urethane construction. Ergonomically carrying handle. Mounting hole for ropes, chains or brackets. Replaceable rubber anti-Skid traction pads with Steel mounting plates to resist skidding of the vehicle.

Applications Includes: Civil Engineering and Construction, Mining, Military Sites, Infrastructure and Utilities Maintenance, Transmission, Heavy Industry.

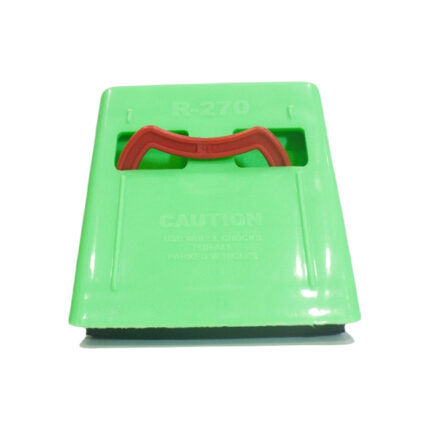

JWC-03 | Jumbo Plastic Wheelchock

Jumbo Wheel chock is manufactured with highly durable, lightweight polyurethane construction.

Our JWC-3 is ideal for use with heavy equipment.

Material: UV Stabilized Polyurethane available in Traffic Yellow, Orange, red or Military green Colour . Tough urethane construction. Ergonomically carrying handle. Mounting hole for ropes,

chains or brackets. Replaceable rubber anti-Skid traction pads with Steel mounting plates to resist skidding of the vehicle.

Material: UV-stabilized polyurethane. Lighter weight with tough urethane construction Complies with SAE-J348, NFPA 1901, 1906, and 1911 Standards. Resistant to oils, fuels and solvents

Applications Includes: Civil Engineering and Construction, underground Mining equipment, Military Sites, underground mining equipment, fire fighting vehicles and large utility vehicles JWC-03 Series is ideal for underground mining equipment, fire fighting vehicles and large utility vehicles.